China’s First Fully 3D-Printed Mini Jet Engine Reaches 4,000 Meters

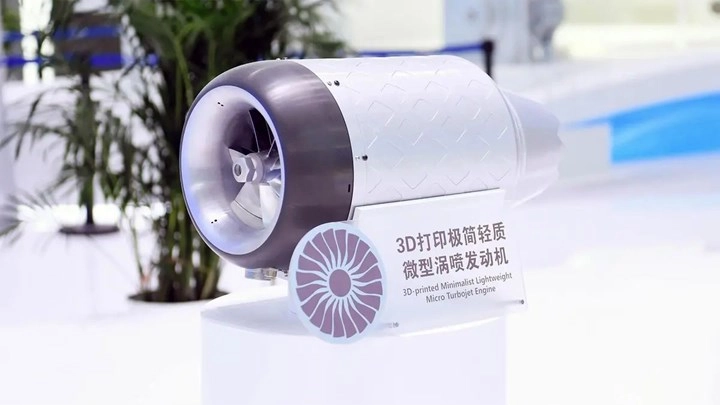

China has successfully test-flown a mini turbojet engine produced entirely with 3D printing technology. This project could offer a significant alternative to traditional engine manufacturing.

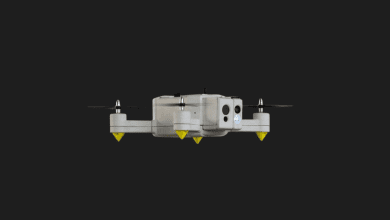

A recent development in China has once again demonstrated the utility of 3D printing in fields requiring complex engineering solutions, such as aviation and defense. China’s state-owned Aero Engine Corporation of China (AECC) successfully conducted the first test flight of a mini turbojet engine manufactured entirely with 3D printers. The flight test, conducted in the Inner Mongolia Autonomous Region, revealed that the engine operated smoothly up to 4,000 meters (approximately 13,000 feet).

This mini jet engine, produced in China, offers a serious alternative to traditional manufacturing methods. AECC highlights that this is China’s first 160 kg class turbojet engine entirely produced via 3D printing and validated by flight.

Advanced Optimization with 3D Printing Could Be the Future of Material Engineering in Aviation

The most striking detail here isn’t just that the engine was produced using 3D printing technology, but that this process was also supported by an advanced engineering approach called “multi-disciplinary topology optimization.” Unlike traditional design processes, this method involves an algorithmic process that calculates not only the shape of a part but also where and at what density a material should be placed. This means engineers can design various components of the engine to be not only durable but also to operate with the lowest possible weight and highest efficiency.

The ideal structure achieved through topology optimization involves geometries too complex to be produced with traditional methods. In classical manufacturing techniques like casting or forging, such intricate integration of parts is either technically impossible or highly labor-intensive. 3D printing removes these limitations. This technology allows for the direct transformation of an optimized digital design into a physical product, enabling integrated manufacturing.

The biggest advantage of this approach is that it both reduces the engine’s weight and significantly increases efficiency in critical parameters such as mechanical strength and thermal performance. According to AECC, this manufacturing model allows complex parts to be produced with fewer connection points and in a more compact form. This enhances the engine’s overall reliability and reduces both production time and cost.

Mini Jet Engines Produced with 3D Printing Can Take UAVs Further

The most suitable short-term application for this engine tested in China is seen as unmanned aerial vehicles (UAVs). Light engines in this class can play a critical role, especially in high-speed and long-range UAV systems.

The fact that such engines are produced with 3D printing offers significant structural and operational advantages for UAV design. Firstly, the weight reduction achieved with topology optimization means longer range and higher altitude capability. This is because every gram is critical in UAVs with limited payload capacity. Furthermore, 3D printing allows complex parts, such as internally cooled turbine components, to be produced with precision impossible with traditional methods, and as a single piece. This increases the engine’s thermal efficiency and reduces overall fuel consumption. Fuel efficiency, in turn, extends mission duration and allows for more operations with less logistical support. Additionally, the digitalization of the production process means that rapid prototyping of such engines and their customization for specific mission profiles could become possible. This could pave the way for much faster and lower-cost development of mission-specific UAV engines in the future.

China Can Reduce Engine Dependence Through 3D Printers

This project, which has seen highly successful initial tests, could offer a significant alternative for China to end its long-standing engine dependence in both military and civil aviation. While 3D-printed materials have been used in jet engines for years, AECC’s project takes it a step further by producing the entire jet engine with 3D printing. Of course, for this project to truly make a difference, it needs to transition to a scalable production line. Whether an investment in this direction will be made will become clear after the tests are completed. AECC officials emphasize that significant technical challenges still need to be overcome for the engine to transition from a single prototype to mass production.